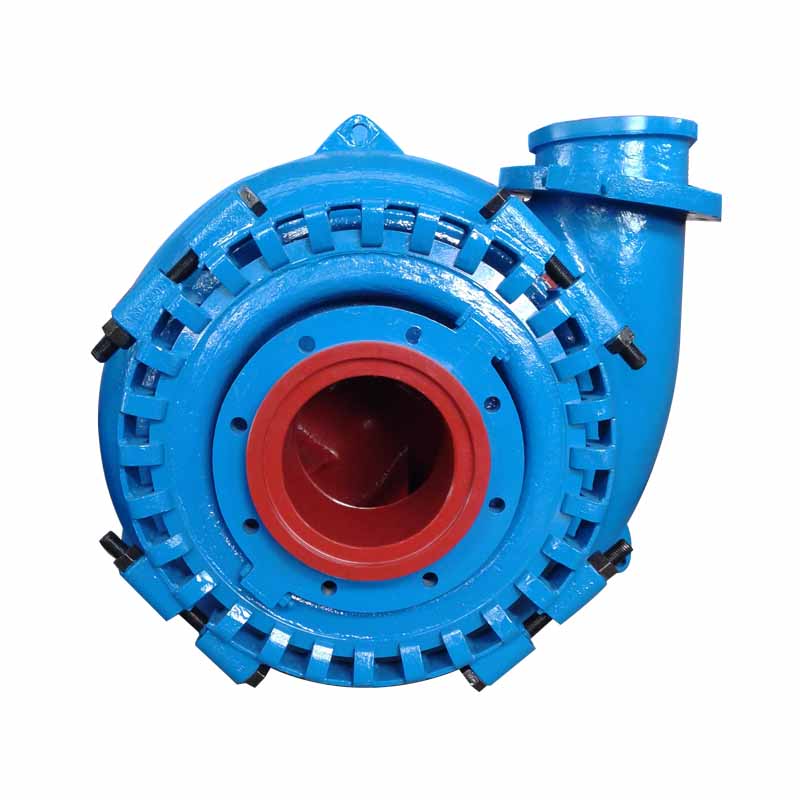

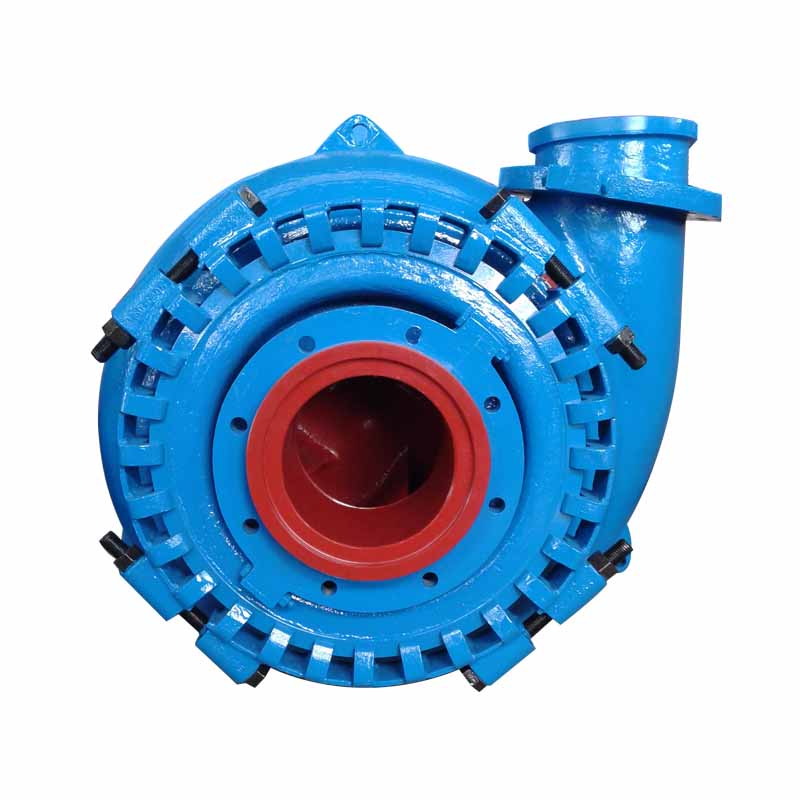

G(GH) Series gravel Pump

Description

The range of Dredge and Gravel pumps is designed specifically for continuous pumping of extremely aggressive slurries, with a wide particle size distribution. Capable of handling large particles at consistently high efficiencies results in low cost of ownership. The large volume internal profile of the casing reduces associated velocities further increasing component life.

Features:

The G(GH) Gravel pump is a horizontal cantilevered single casing centrifugal pump.

A typical feature of this sand and gravel pump is its one-piece case, connected using clamp bands. This design makes the outlet rotation to any angle. Minimal maintenance is required.Wide flow passage allows a large volume of slurry to pass. The sand and gravel pump is specially designed to handle high-abrasion applications that ordinary pumps can't even attempt.One-piece case and wear-resistant hydraulic parts are easy to replace and repair.The pump head is fixed to the mounting base by a few bolts. Users can adjust the clearance between the impeller and suction liner from underneath a bearing pedestal.Three shaft seal types are available. Packing seal. Expeller seal and special engineered seal. Users can easily replace one type of seal with another in order suit the specific pumping application.

Applications:

delivering slurries in Mining

Explosive sludge in metal melting

Dredging in dredger and course of rivers

Other fields

Performance Data:

|

Model Type |

Capacity |

Head |

Speed |

Efficiency |

NPSHr |

Inlet Diameter |

Outlet Diameter |

Max Diameter Flowed Particle |

||

|

(l/s) |

(m3/h) |

(m) |

(r/min) |

(%) |

(m) |

(mm) |

(mm) |

(mm) |

||

|

|

6/4D-G |

10-70 |

36-252 |

3.5-51 |

600-1400 |

30-50 |

2.5-3.5 |

150 |

100 |

82 |

|

|

8/6E-G |

38-161 |

137-580 |

10-48 |

800-1400 |

50-60 |

3-4.5 |

200 |

150 |

127 |

|

|

10/8S-G |

60-272 |

220-1000 |

13-50 |

500-1000 |

45-65 |

3-7.5 |

250 |

200 |

178 |

|

|

10/8F-G |

60-272 |

220-1000 |

13-50 |

500-1000 |

45-65 |

3-7.5 |

250 |

200 |

178 |

|

|

12/10F-G |

100-420 |

360-1520 |

11-58 |

400-850 |

50-70 |

2-4.5 |

300 |

250 |

220 |

|

|

12/10G-G |

100-420 |

360-1520 |

11-58 |

400-850 |

50-70 |

2-4.5 |

300 |

250 |

220 |

|

|

14/12G-G |

140-880 |

500-3100 |

6-66 |

300-700 |

60-68 |

2-8.0 |

350 |

300 |

241 |

|

|

18/16G-G |

240-1060 |

860-3800 |

9-48 |

250-500 |

60-72 |

3-6.0 |

450 |

400 |

254 |

|

|

18/16T-G |

240-1060 |

860-3800 |

9-48 |

250-500 |

60-72 |

3-6.0 |

450 |

400 |

254 |

|

|

10/8S-GH |

110-360 |

600-2200 |

18-80 |

500-950 |

60-72 |

2-5.0 |

250 |

200 |

180 |

|

|

12/10T-GH |

170-260 |

400-1290 |

28-78 |

350-700 |

60-72 |

2-8.0 |

300 |

250 |

210 |

|

|

16/14TU-GH |

200-1000 |

720-3600 |

20-72 |

300-500 |

60-72 |

3-6.0 |

400 |

350 |

230 |

Material

|

Parts |

Material |

Specification |

|

Volute Liner Impeller Throat bush Frame plate liner insert Throat bush |

Hard Metal |

T05: KmTBCr26 T07: KmTBCr15Mo Chrome White Iron |

|

Rubber |

R26 R08 R55 R33 S01 EPDM S31 S44 |

|

|

Expeller&Expeller Ring |

Metal |

T05:KmTBCr26 T07:KmTBCr15Mo Chrome White Iron |

|

Rubber |

R26 R08 R55 R33 S01 EPDM S31 S44 |

|

|

Stuffing Box |

Metal |

T05: KmTBCr26 T07: KmTBCr15Mo Chrome White Iron

|

|

Frame Plate Cover Plate Base Bearing housing |

Metal |

G01 Gray Iron |

|

Shaft |

Carbon Steel |

Type 1045(ASTM) |

|

Shaft Sleeve Lantern Rings Restrictor Neck Ring Gland Bolts |

Stainless Steel |

3Cr13,304SS,316SS |

|

Joint Ring&Seals |

Rubber |

R26 R08 R55 R33 S01 EPDM S31 S44 |

Application Photo: