Oilfield sevices C-pump

C-pumps, or centrifugal pumps, are used extensively in the oil and gas industry due to their effectiveness in handling various fluid management tasks required during drilling, production, and maintenance operations.most use mission magnum pump as C-pump in oilfield services.

Here’s why C-pumps are crucial in this sector:

Here’s why C-pumps are crucial in this sector:

1. Efficient Fluid Circulation

High Flow Rates: C-pumps are capable of moving large volumes of fluids efficiently, which is essential in drilling operations where high flow rates are necessary to circulate drilling mud (or fluid) through the wellbore.

Consistent Performance: They provide a consistent and continuous flow of fluids, which helps in maintaining stable pressure and volume throughout the drilling process.

2. Versatility in Applications

Drilling Fluids Management: C-pumps are used to circulate drilling fluids, which cool and lubricate the drill bit, transport cuttings from the wellbore to the surface, and help maintain the pressure to prevent blowouts.

Hydraulic Fracturing: In hydraulic fracturing (fracking), C-pumps inject fracturing fluids into the wellbore under high pressure to create fractures in rock formations, allowing for the extraction of hydrocarbons.

Acidizing Operations: They are used in acidizing to pump acid solutions into the well to dissolve rock formations and improve the flow of oil or gas.

3. Handling High Pressures

Robust Design: C-pumps are designed to handle high pressures, which is critical for maintaining the pressure needed in drilling and fracking operations. This robustness ensures the pump can withstand the demanding conditions of deep well operations.

Pressure Regulation: These pumps often come with adjustable settings that allow operators to control and optimize the pressure and flow rates according to the specific needs of the operation.

4. Durability and Reliability

Wear-Resistant Materials: The components of C-pumps are made from materials that resist wear and corrosion caused by abrasive and corrosive drilling fluids. This durability ensures longer operational life and reduces the need for frequent replacements

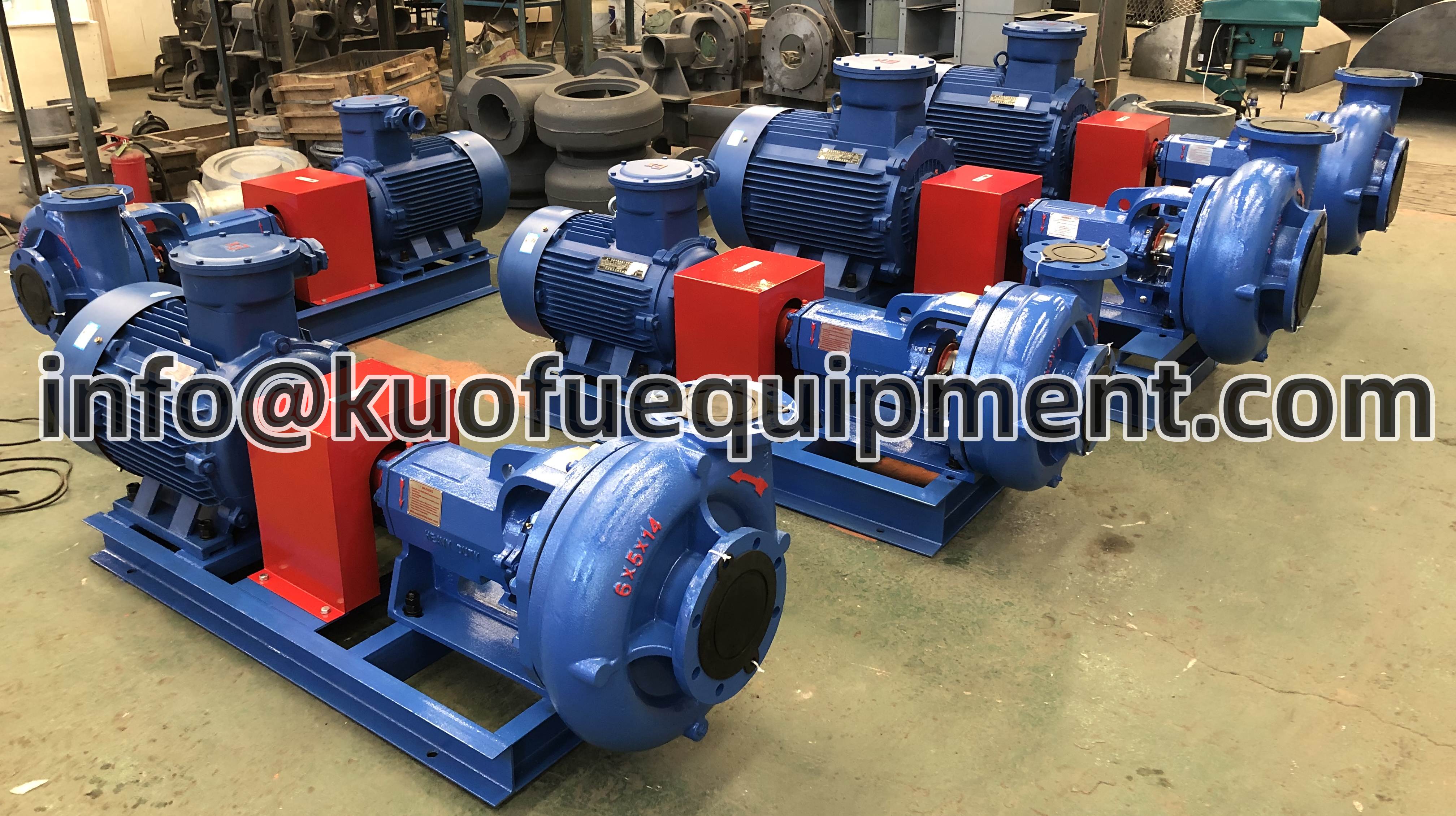

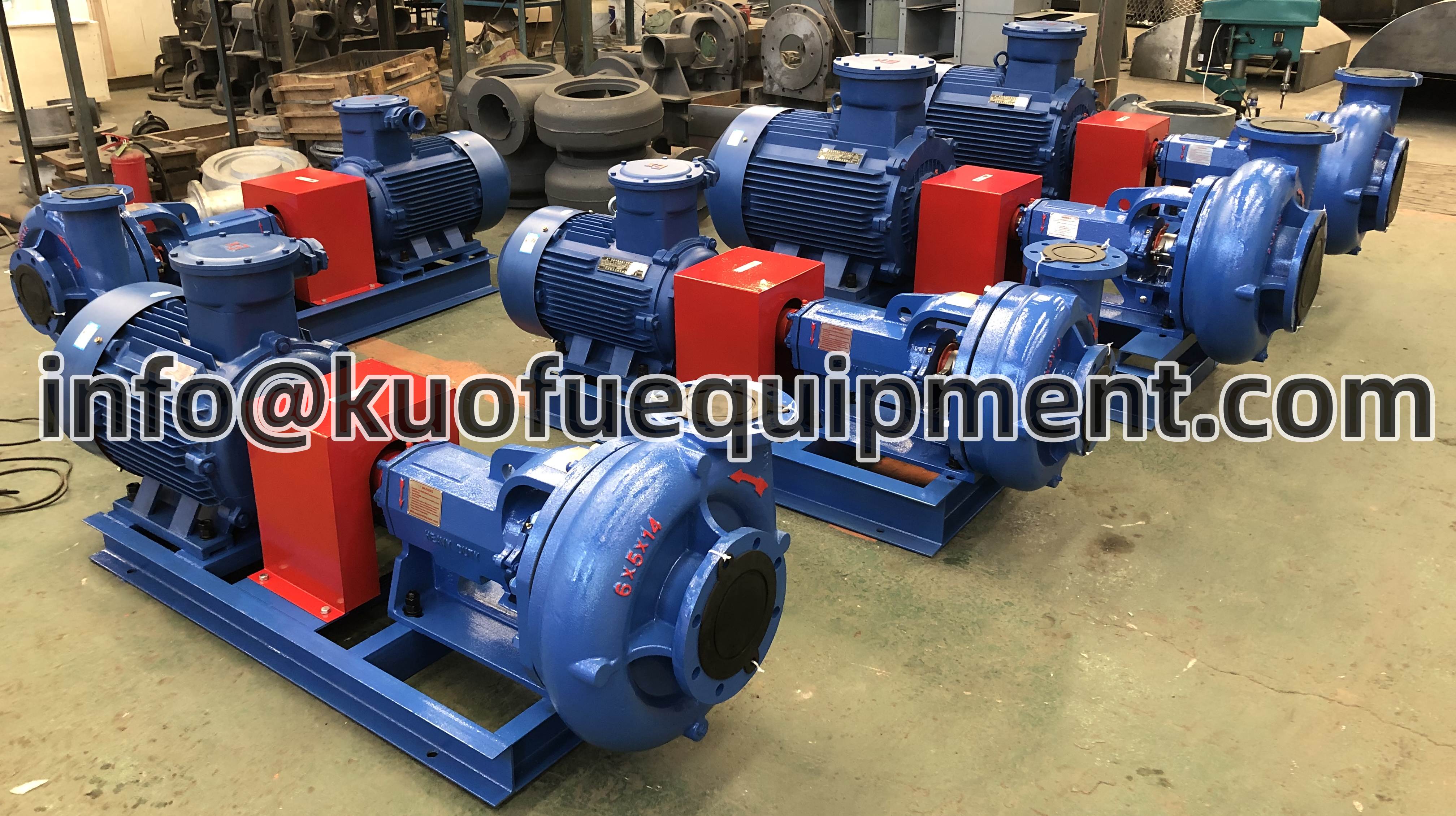

Kuofu Equipment provide C-pump/centrifugal sand pumps to suit for all kinds of drilling sand pump application. Size ranges from 3x2x13, 4x3x13, 5x4x14, 6x5x11,6x5x14, 8x6x11,8x6x14, 10x8x14, 12x10x23 to 14x12x22b. Bare pumps, matching motors are available from 7.5KW to 90KW, with rotation 800, 1000, 1150,1450, 1750 to 3500 RPM at 50Hz or 60Hz.

Kuofu Equipment provide C-pump/centrifugal sand pumps to suit for all kinds of drilling sand pump application. Size ranges from 3x2x13, 4x3x13, 5x4x14, 6x5x11,6x5x14, 8x6x11,8x6x14, 10x8x14, 12x10x23 to 14x12x22b. Bare pumps, matching motors are available from 7.5KW to 90KW, with rotation 800, 1000, 1150,1450, 1750 to 3500 RPM at 50Hz or 60Hz.

The model 10x8x14 and 8x6x14 centrifugal magnum pump used on solid control system over 3000 meter-long drilling rigs, with big viscosity and heavy specific gravity drilling fluid. 8x6x11 centrifugal mud solid control feeding pump applies to under 3000 meter-long drilling rigs, and it also can be used to supply mud to triplex mud pump as a filling pump. 6×5×11 centrifugal pump applies to truck-mounted drilling rigs or pocket drilling rigs. 4x3x13 drilling centrifugal pump is usually used as measuring pump or replenishment pump. 3x2x13 model pump is usually used as clean water pump.

* Kuofu® is a registered trademark and does not represent or is not in any way affiliated with Mission Magnum® of NOV Group. All names,numbers, symbols and descriptions are used for reference purpose only and do not imply that any pumps or parts listed is the product of Mission Magnum Pumps.

* Kuofu® sand pumps and spares are only interchangeable with Mission Magnum pumps and spares.

* This document is the property of Kuofu® Pump and can be neither reproduced nor disclosed to a third party without a written authorization.