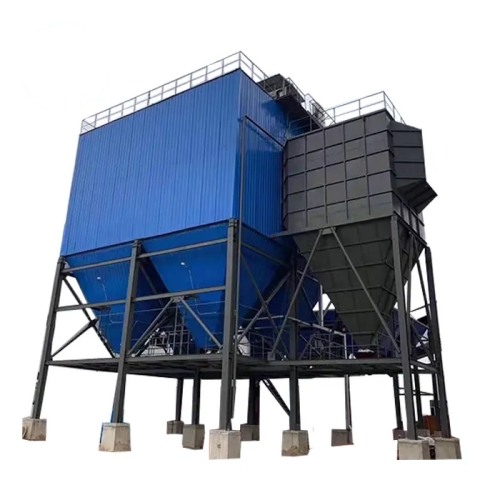

PPCS Series Bag Type Dust Collector

Description

PPC type air box pulse dust collector is with the introduction of technology manufacturing. It combines the advantages of a sub-room cleaning and pulse cleaning of the baghouse, thereby it can expand the scope of application of the baghouse, improve the collection efficiency and extend the service life of the bag. This series of dust collector is composed of a number of different rooms and the number of different bags per room combined into a variety of specifications, the number of bags per room has 32, 64, 96, 128 bags, 33 kinds of specifications. The dust collector of this series can be positive or negative pressure operation, the basic structure is without any changes.

PPC series of dust collector inlet concentration up to 1000g/M3, its collection efficiency can reach 99%. The use of polyester 208 filter temperature is 120 ° C, allowing the application of glass fiber needle felt filter temperature is 210 ℃.

Scope of application

PPC series dust collector are widely used in crushing, packing, top of your library, clinker cooler and various types of mills and other dust collection system of a cement plant for the coal mill dust with anti-blasting measures.

Main technical specification

| Type | Air Capacity(m³/h) | Gross filtration area(m³) | Net filtration area(m³) | Chamber Qty. | Filter bag |

Air consumption (m³/min) |

Impeller-type feeder | Tube screw conveyor | Air conveying slides | |

| Qty. | spec. | |||||||||

| PPCS32-3 | 6900 | 93 | 62 | 3 | 96 |

130× 2450 mm |

0.27 |

300×300(mm) motor power 1.1KW |

- | |

| PPCS32-4 | 8930 | 124 | 93 | 4 | 128 | 0.37 | - | |||

| PPCS32-5 | 11160 | 155 | 124 | 5 | 160 | 0.46 | - | |||

| PPCS32-6 | 13390 | 186 | 155 | 5 | 192 | 0.55 | - | |||

| PPCS64-4 | 17800 | 248 | 186 | 4 | 256 | 1.2 |

300mm30m³/h motor power 2.2KW |

- | ||

| PPCS64-5 | 22300 | 310 | 248 | 5 | 320 | 1.5 | - | |||

| PPCS64-6 | 26700 | 372 | 310 | 6 | 384 | 1.8 | - | |||

| PPCS64-7 | 31200 | 434 | 372 | 7 | 448 | 2.1 | - | |||

| PPCS64-8 | 35700 | 496 | 434 | 8 | 512 | 2.4 | - | |||

| PPCS96-4 | 26800 | 372 | 279 | 4 | 384 | 1.2 | 400×400(mm) motor power1.5KW |

400mm38 (m³/h ) motor power 5.5KW |

- | |

| PPCS96-5 | 33400 | 465 | 372 | 5 | 480 | 1.5 | - | |||

| PPCS96-6 | 40100 | 557 | 465 | 56 | 576 | 1.8 | - | |||

| PPCS96-7 | 46800 | 650 | 557 | 7 | 672 | 2.1 | - | |||

| PPCS96-8 | 53510 | 744 | 650 | 8 | 768 | 2.4 | - | |||

| PPCS96-9 | 60100 | 836 | 744 | 9 | 864 | 2.7 | - | |||

| PPCS96-2×5 | 66900 | 929 | 836 | 10 | 960 | 3.0 |

2 sets 350×350(mm) motor power 2×1.5KW |

2 sets 300mm2X21m³/h motor power 2.2KW | - | |

| PPCS96-2×6 | 80700 | 1121 | 1028 | 12 | 1152 | 3.4 | - | |||

| PPCS96-2×7 | 94100 | 1308 | 1251 | 14 | 1344 | 4.2 | - | |||

| PPCS96-2×8 | 107600 | 1494 | 1401 | 16 | 1536 | 4.8 | - | |||

| PPCS96-2×9 | 121000 | 1681 | 1588 | 18 | 1728 | 5.4 | - | |||

| PPCS96-2×10 | 134500 | 1868 | 1775 | 20 | 1920 | 6.0 | - | |||

| PPCS128-6 | 67300 | 935 | 779 | 6 | 768 |

130× 3060 mm |

3.6 | 300×300(mm) 1.1KW | 300mm motor power 2.2KW |

- - - |

| PPCS128-9 | 100900 | 1402 | 1246 | 9 | 1152 | 5.4 | ||||

| PPCS128-10 | 112100 | 1558 | 1402 | 10 | 1280 | 6.0 | ||||

| PPCA128-2×6 | 134600 | 1869 | 1713 | 12 | 1536 | 7.0 | 305×915(mm) motor power XWD4-7-1/371.1KW |

B250mm Air volume required 2m³/m2 |

||

| PPCA128-2×7 | 157000 | 2181 | 2025 | 14 | 1792 | 8.3 | ||||

| PPCA128-2×8 | 179400 | 2492 | 2336 | 16 | 2084 | 9.5 | ||||

| PPCA128-2×9 | 201900 | 2804 | 2648 | 18 | 2304 | 10.7 | ||||

| PPCA128-2×10 | 224300 | 3115 | 2959 | 20 | 2560 | 12 | ||||

| PPCA128-2×11 | 247600 | 3427 | 3271 | 22 | 2816 | 13.1 | ||||

| PPCA128-2×12 | 269100 | 3738 | 3582 | 24 | 3072 | 14.3 | ||||

| PPCA128-2×13 | 294600 | 4050 | 3894 | 26 | 3328 | 15.5 | ||||

| PPCA128-2×14 | 314000 | 4361 | 4205 | 28 | 3584 | 16.7 | ||||